The HVAC industry, climate change and technological progress

With an expert eye

Anna Pawłowska-Kawa, specialist in the field of ecological heating devices

The heating, ventilation, and air conditioning (HVAC) industry need to undergo adaptation in response to the continuously evolving reality shaped by climate change. Acknowledging our collective inability to halt climate change, the industry must now proactively align itself with this new environmental context. Additionally, embracing the opportunities presented by the advancement of intelligent systems, particularly artificial intelligence, is imperative for staying at the forefront of innovation and efficiency.

Climate change is unfolding rapidly, surpassing scientists’ predictions and leaving a visible impact worldwide. Glaciers are melting, contributing to rising sea and ocean levels. The global average temperature is on the rise, and in Poland, September of this year marked the warmest on record. The frequency of extreme and violent weather events is escalating, with previously unaffected regions now grappling with uncharacteristic heatwaves and droughts. This shift has adverse effects on health, life, the global economy, and social phenomena, including population migration.

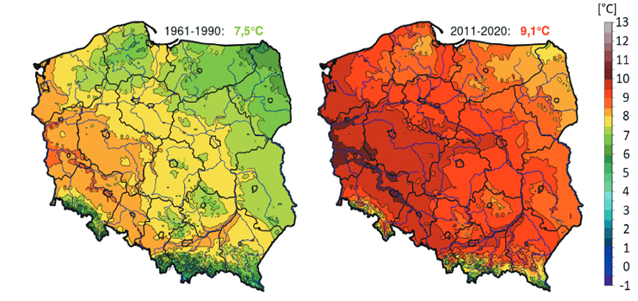

The discernible increase in Poland’s average temperature is effectively illustrated through maps prepared by IMWM.

Average annual air temperature in Poland: in 1961–1990 (left), in 2011–2020 (right).

The HVAC (heating, ventilation, and air conditioning) industry is grappling with the impacts of climate change, particularly in the heating sector, where it is becoming increasingly evident that the industry is struggling to keep pace with these changes. The fundamental issue lies in the fact that the standards guiding Polish heating system designers are rooted in practices from half a century ago. These outdated standards, including design temperature distributions, serve as the foundation for developing the energy characteristics of buildings and form the basis for thermal load calculations and energy certificates. However, the challenge lies in the substantial shifts in average temperatures in Poland over the past 50 years, rendering these long-standing standards less relevant to the current climate reality.

Standards update

Crucially, several European countries, including Germany, have proactively updated their design temperatures multiple times. Despite periodic warnings from experts about the outdated standards in Poland, the issue had not been taken seriously until now. Dr. Eng. Piotr Narowski, a scientist from the Warsaw University of Technology, initiated a project addressing this concern by proposing changes to the current calculation temperatures for all climatic zones in Poland (Projects SKP2000 and TLM2000). The project was supported by the Polish Organization for the Development of Heat Pump Technology (PORT PC), the Association of Producers and Importers of Heating Devices (SPIUG), and KAN sp. z o.o., a company specializing in installation systems.

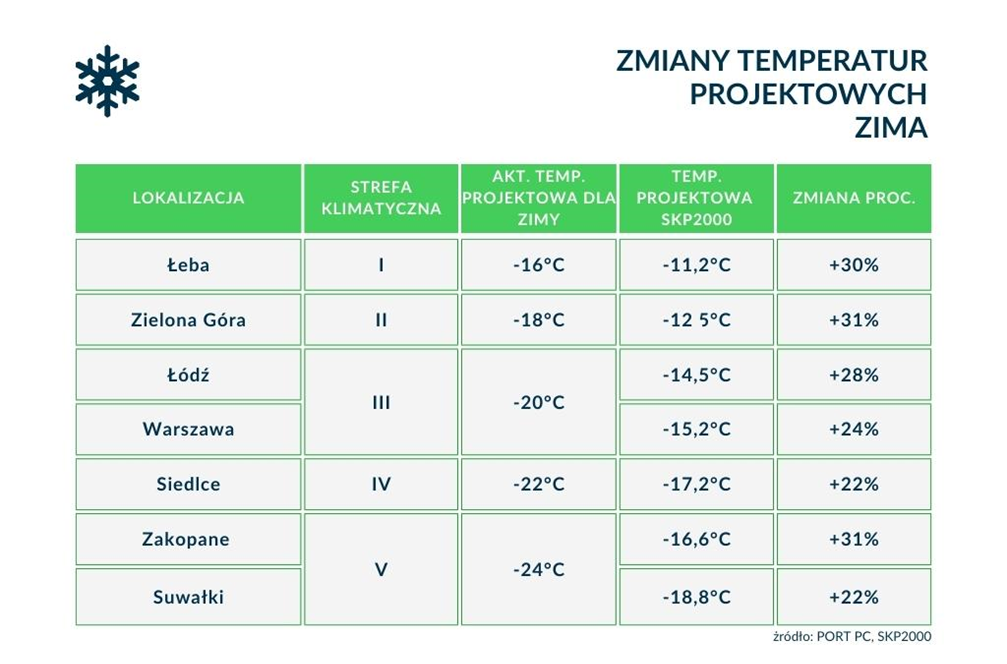

Over the last decade, the average annual area temperature in Poland has risen to 9.1℃, compared to 7.5℃ in the years 1961-1990. Notably, recent years have witnessed record-breaking average annual temperatures, with readings of 9.1℃ in 2000, 9.3℃ in 2014, 9.5℃ in 2018, and a substantial 9.9℃ in 2019. It is essential to highlight that, historically, the annual average had rarely surpassed 10℃, and this was based on local point values rather than the area average. A comparison of temperature data from the past decade in specific locations with the data in applicable HVAC standards clearly indicates the presence of outdated design temperatures. These design temperatures, a fundamental parameter for the optimal design of heating, ventilation, and air conditioning systems, need to be revised. The changes in design temperatures for the winter months are detailed in the table below:

On average, the design temperature for heating systems is approximately 27% higher than the temperatures specified in applicable standards. This discrepancy implies that the heating devices’ power may be overestimated by roughly 13% at present. The clear takeaway is that both the Technical Conditions and the annex to the PN-EN 12831 standard demand thorough editing and updating. Conversely, for summer months, variations between the temperatures outlined in the applicable standard PN-76/B-03420 and the average temperatures recorded from 1991 to 2020 are minimal.

Except for areas situated at high altitudes, it can be reasonably assumed that the temperatures used for air conditioning and ventilation design are currently accurate.

Oversized heating devices – why are they a problem?

A few decades ago, oversizing heating devices, particularly coal-fired boilers, was a standard practice. The idea was to have the boiler provide sufficient heat in case of severe cold, with a larger exchanger presumed to generate more warmth. This approach was influenced by the state of the buildings, which often lacked proper insulation, allowing heat to escape through uninsulated walls, leaky doors, and windows. In single-family houses, boilers with capacities as high as 29, 36, or even 42 kW were commonly installed, primarily due to the abundance of coal and a notion of “better safe than sorry.”

However, with advancements in house construction technology and improved insulation, the need for such oversized boilers has diminished. Boilers with a maximum power of 20 kW are now typically sufficient, depending on factors like area, installation type, and hot water demand. The outdated practice of selecting an excessively large boiler has several disadvantages, as it burns more fuel without guaranteeing better energy efficiency, leading to increased contaminants in the exchanger and chimney and a shortened device lifespan. An oversized solid fuel boiler operates most efficiently at its nominal power, and an oversized one struggles to achieve it.

Regrettably, this habit of choosing devices with a power reserve has seeped into the heat pump industry as well. When calculation temperatures are set higher than actual conditions, and additional kilowatts are added “just in case,” the final heat pump may end up with a power 20-30% higher than necessary. This not only results in lower system efficiency and higher investment costs but also shortens the compressor’s lifespan due to exceeded power regulation ranges and increased electricity consumption.

While it might seem that designers, relying on lower calculation temperatures, lead to most heat pumps being oversized, market signals suggest a different reality. Investors often push for lower-power units to cut costs, overlooking the fact that an underestimated heat pump power leads to higher electricity bills and more expensive operation. A heat pump is equipped with an electric heater that serves as a supplementary source during extremely low temperatures. For the heating to be both eco-friendly and economical, the heat pump’s power should be selected to operate efficiently without the heater for 95-99% of the time. If the heat pump’s power is too low, the heater’s usage time increases, resulting in unnecessary costs.

This underscores the importance of professional and accurate device power selection, accounting for climate change while avoiding underestimation of the actual power required. It’s crucial to avoid practices that may appear cost-effective initially but lead to higher operational expenses in the long run. The surge in heat pump adoption has also seen the emergence of new installation companies, and it is essential for these entities to update their knowledge through training with manufacturers and gain practical competence in this evolving field.

The HVAC industry and the potential of artificial intelligence

The 21st century is not only about the effects of a warming climate and related problems, but also about incredible technological progress. We hear more and more often about artificial intelligence (AI) and in a much broader sense than the possibilities of a chat that writes essays for students on any topic. The “intelligence” of systems is nothing else than their ability to interpret, learn and draw conclusions from the environment in order to optimize it. HVAC systems can benefit from this by adapting energy consumption to actual needs, which directly leads to lower bills. Artificial intelligence is also able to “learn” users’ habits and control the temperature to ensure the required thermal comfort in each zone. AI-supported installations can perform self-diagnostics, constantly monitor their technical condition, predict potential failures and threats, which reduces their failure rate and interruptions in operation.What does it look like in practice? The results of the experiment conducted inSingapore, which were published in October last year, are interesting. The study covered office buildings that had problems with thermal comfort – hot and cold places as a result of suboptimal air distribution. This was supposed to be fixed by the so-called proactive control, allowing dynamic adjustment of air flows and water cooling depending on the current heat loads for each subzone. The results were compared with the existing control and it turned out that not only were cold and hot spots eliminated and thermal comfort was ensured, but also energy costs were reduced. The demand for electricity for ventilation decreased by 50% and for air conditioning by 29%.

An intelligent heating system will be built in Lublin

Polish cities are leveraging artificial intelligence to enhance the energy sector. Lubelskie Przedsiębiorstwo Energetyki Cieplnej (LPEC), in collaboration with the Lublin University of Technology and the City of Lublin, has revealed plans for the development of an Intelligent Heating System this spring. This innovative project is primarily designed to optimize the city’s heating network. Simultaneously, it aims to serve as an educational initiative for students and PhD candidates at Lublin University of Technology and enhance the qualifications of LPEC employees.

SourceSource: LPEC

Scientists are developing artificial intelligence algorithms to design and implement an optimized heating system. The goal is to achieve maximum thermal comfort for consumers with minimal energy input. Marek Gołuch, president of LPEC, emphasizes that intelligent heating systems utilize advanced management and monitoring systems to efficiently supply heat to buildings. These systems integrate various elements, including heat sources, transmission networks, heat nodes, and communication tools, to optimize thermal energy management.

The advanced IT systems will dynamically adjust heat production and transmission in real time based on residents’ current needs, preventing energy wastage. The Intelligent Heating System in Lublin aims to eventually integrate renewable energy sources such as biomass, solar, and geothermal energy. The development of monitoring software will help identify and address losses in the heating network swiftly, enhancing efficiency and reducing costs. These initiatives not only contribute to energy transformation but also foster the overall development of the city, making it more attractive for investment, work, and living.

Anna Pawłowska-Kawa

A graduate of the Kielce University of Technology, majoring in Management, Production Engineer, and Mechanics and Machine Construction. A specialist in the field of ecological heating devices. A supporter of a systemic and sustainable approach to the issue of energy transformation.